Beyond the pipeline

Why nonmetallics are the oil and gas industry’s 21st century solution.

-

Nonmetallic solutions can benefit the global energy industry, diversifying business streams and promoting sustainability

-

Sectors impacted include: building and construction; automotive; packaging; renewables; oil and gas

-

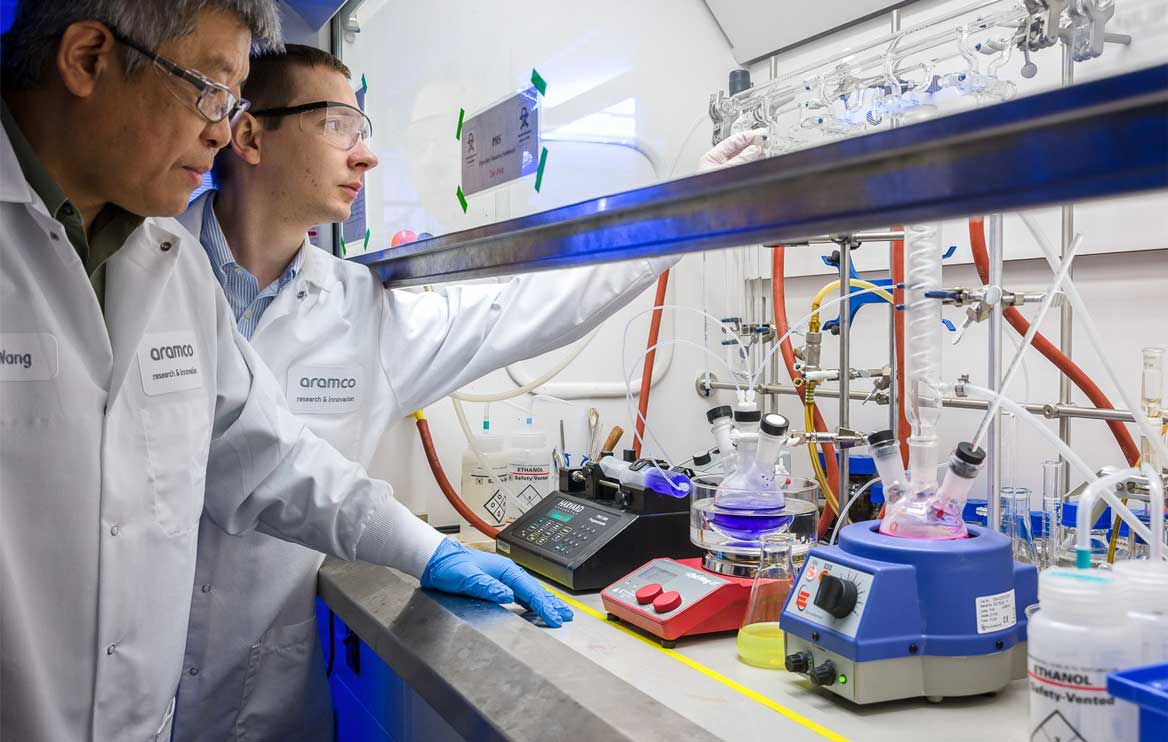

Aramco established the Non-metallic Innovation Centre to promote global use of nonmetallic materials and to advance related technologies

From the moment crude oil is brought to the Earth’s surface, to the point of its consumption as fuels or other petroleum products, oil and gas liquids pass through a series of onshore and offshore pipelines that link refining and distribution facilities. Whether the hydrocarbons are being gathered or transmitted, this highly integrated grid, aided by innovative methods and state-of-the-art technology, gets the energy where it needs to go — safely, efficiently, and sustainably.

As the world’s most reliable energy supplier, Aramco must ensure that its network spanning thousands of square kilometers sets the industry standard for reliability. Such a critical infrastructure calls for materials that can diminish potential problems like corrosion and leaking, are easier to maintain, and carry lower long-term costs.

This quest led us to embark on a journey to innovate these materials for the benefit of the global energy industry and manufacturing sectors, as well as produce the chemicals to fabricate them from our own oil. But, as it turns out, piping is just the tip of the iceberg.

This is Aramco’s nonmetallic journey.

A logical path

The venture into nonmetallics is a logical step for our Company as an integrated energy and chemicals company. Our role in the global industry, plus the scale and scope of our own pipeline and facilities network, calls for research and innovation to ensure that this major component of our business more than stands up to severe and erosive conditions.

Our role in the global oil and gas industry, plus the scale and scope of our own pipeline and facilities network, means that our venture into nonmetallics is a logical step.

Pipelines are built to be safe, but corrosion is a natural consequence of metal use, and must be monitored and managed. Called “the invisible enemy” for a reason, corrosion costs industries around the world billions of dollars each year in prevention, maintenance, and repair expenses. Some sources put corrosion costs for the oil and gas industry alone at more than $60 billion. Fighting the gradual return of metal to its natural state is especially important for our sector, as component failure can mean not just costly interruption of business, but environmental consequences.

The decision to develop a suite of advanced polymeric solutions for the petroleum industry, and beyond, meshes with Aramco’s strategic aims to derive the maximum value from our hydrocarbons, to include new, alternative applications. And of course, it aligns with our signature technology and innovation focus.

Innovating technical excellence

To develop field-applied solutions that meet strict temperature and pressure tolerance for nonmetallic materials, we have established a Non-metallic Innovation Centre (NIC) in Cambridge, England, in collaboration with The Welding Institute and Abu Dhabi National Oil Company. The NIC brings together partners from academia, oil and gas companies, composite material manufacturers, and other research entities to fast-track product development, testing, and commercialization.

The Khurais megaproject brought the use of nonmetallics to a new level; 400 kilometers of nonmetallic flowlines were installed.

The industry’s need for nonmetallic materials is growing, but our studies revealed that the technical limitations of currently available materials were responsible for their slow penetration. Clearly, the right noncorrosive alternatives could address temperature/pressure and chemical compatibility issues to enhance the safety and environmental performance of oil and gas production. As a center of technological excellence, the NIC can test and catalyze products with the right advanced properties and characteristics – and, moreover, work with customers on their own technical priorities.

Aramco’s own application of nonmetallics is not new. We use nonmetallic pipe in the majority of our oil and gas facilities; it is also standard for most utility applications in our plants.

But it was our first mass deployment of reinforced thermoplastic pipe (RTP) in a newly developed oilfield increment of our Khurais megaproject that brought our use of the material to a new level. Following intensive lab and field testing to ensure alignment with Aramco’s rigorous standards, 400 kilometers of nonmetallic flowlines were installed, versus standard carbon steel pipelines.

Life-cycle costs of RTP were determined to be a third of carbon-steel pipe, thanks to the elimination of corrosion monitoring costs.

Installation time also revealed a stunning contrast, with the Khurais RTP flowline construction coming in at less than two days, compared to the typical 70 days for laying carbon steel.

Our tests also endorsed RTP’s safety advantages, including the pipe’s lighter weight that made it easier to transport and install, and the elimination of some tasks including welding.

The chemistry of nonmetallics

These contrasts, though, aren’t the whole story. The real breakthrough is the technology we’re developing that can streamline the nonmetallics sector.

Aramco’s ambition to innovate with oil, transforming crude oil directly into valuable petrochemicals — a process that eliminates the refinery stage — is part of our corporate nonmetallics strategy. Crude-oil-to-chemicals technology, or C2C, could position the Company to more efficiently create the chemicals that companies will use to fabricate materials. Promoting hydrocarbon conversion is the first step in a technology focus that addresses industry challenges, then accelerates the deployment of solutions.

Pushing the envelope

This strategic focus on nonmetallic solutions has expanded the operating envelope. These advanced materials can bring lower life-cycle cost advantages, flexibility, and durability to the packaging, automotive, and building and construction sectors, to name a few. Carbon fibers are making inroads in several industries. Not only are they replacing steel in the automotive industry, the high strength-to-weight ratio makes them an ideal choice for many other applications, including wind turbine blades and composite pipe for deep sea oil wells.

By positioning Saudi Arabia to become a nonmetallic materials hub, we’re advancing our Company’s local content efforts and aligning with the Kingdom’s Vision 2030 economic diversification goals.

As we innovate for better reliability, safety, cost control, and overall integrity in nonmetallics for the oil and gas industry — and uncover new applications in other sectors — we’re creating a true win-win proposition: increasing demand for oil, innovating our resources for more and better products, and creating opportunity for manufacturers.

That’s our nonmetallic solution.

More from Elements

The material in this article is intended to be for general informational purposes only, and readers should not place undue reliance on the statements or opinions therein. Any information provided speaks only as of the date this content was published and Saudi Aramco undertakes no obligation to correct, update, or revise any statements or opinions made in or implied by this article.