Aramco’s historic ‘No. 1’ wells

The stories of four of the wildcat exploratory wells that paved the way for decades of discovery and our industry-leading operations.

- Aramco’s wildcat wells — ‘Ain Dar, Safaniyah, Khursaniyah, and Zuluf — are a testament to our history of striving for Upstream excellence

- Decades after being drilled for exploration, most of these wells still continue to produce oil, gas, or both

- This is made possible due to the continuous adoption of new, improved extraction technologies and industry best practices

On April 30, 1935, drilling started on Well No. 1 in Dammam, marking the start of Aramco’s journey as one of the world’s leading and largest hydrocarbon producers. In the 90 years since then, we have continued to unearth the vast natural resources of Saudi Arabia, uncovering numerous reservoirs across the Kingdom — many of which have been abundant with oil, gas, or both.

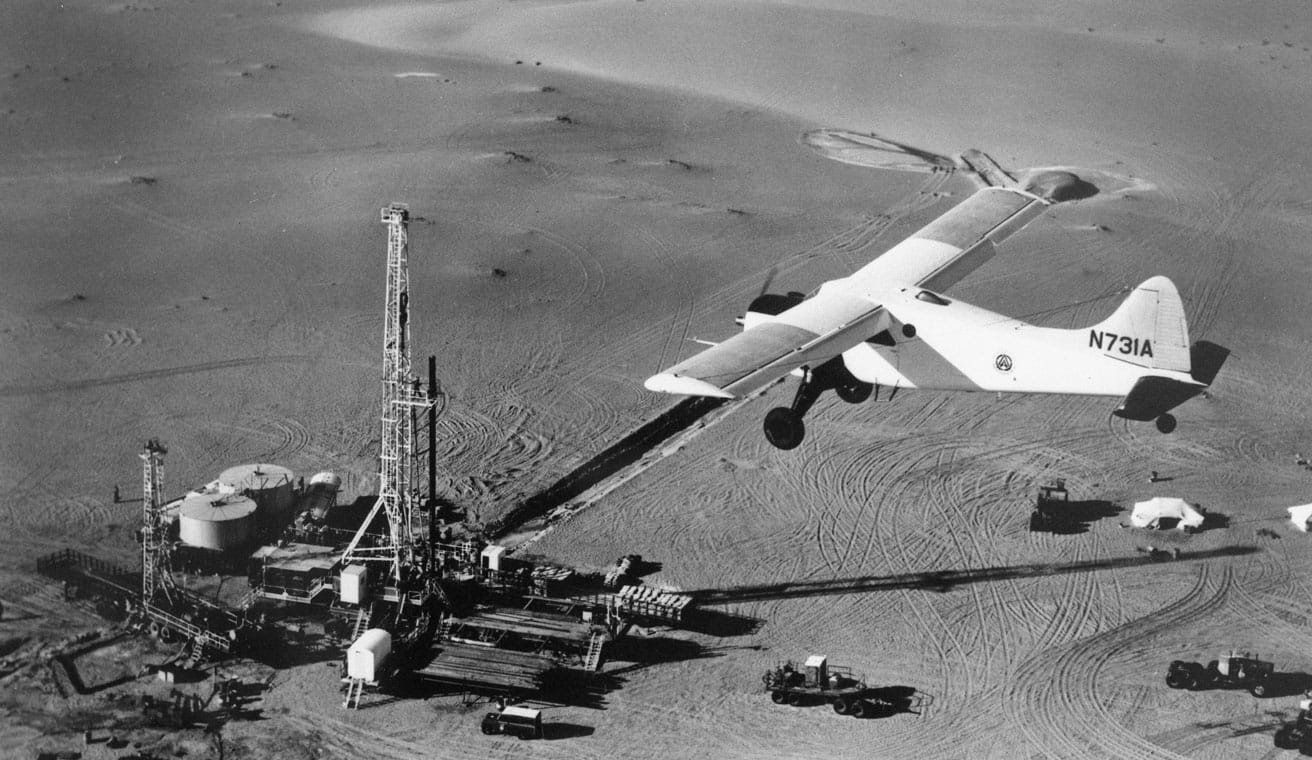

But despite geological expertise, and potentially a wealth of positive signs, no discovery is ever truly certain until the ‘wildcat’ or ‘exploration’ well has been drilled and confirmed what truly lies beneath. The first well to be drilled in an area, a ‘wildcat’ (Well No. 1) is inherently risky. They are often being drilled in a previously unknown, unpopulated, and frequently remote location. It’s more ‘expedition’ than a standard day of work, and success is never guaranteed. This is why finding oil from the area's first well is a significant accomplishment in any exploration effort.

Our ‘historic’ wells

During the early years, the first phase of establishing the presence of an oil field was the search by our geologists above and below ground for the geological features that would indicate the potential for oil and gas reservoirs to be hidden below. The next vital decision was where to drill the wildcat well. If the wildcat turned up oil in commercial quantity, it would thereafter be called the discovery well for this newly-discovered field.

In any exploration effort, finding oil from the area’s first well, also known as a ‘wildcat’ or ‘exploration’ well, confirms what truly lies beneath the surface.

The stories of Aramco’s wildcat wells — ‘Ain Dar, Safaniyah, Khursaniyah, and Zuluf — are just four examples out of the hundreds of Aramco wells across the Kingdom that showcase our history of striving for Upstream excellence and the complex process behind each hydrocarbon discovery.

“Our historic No. 1 wells hold great importance to us as not only did they mark the beginning of a new era in our crude production history but also have continued to yield significant returns over several decades.

These wells have stood the test of time, providing an enduring testament to the ingenuity and legacy of our reservoir management practices, unlocking the vast potential of the Kingdom's energy resources.”

Waleed A. Al Mulhim

Aramco’s Senior Vice President of Petroleum Engineering and Development

ANDR-1 ('Ain Dar)

Start of production: 1948

Cumulative production: 160.2 million stock tank barrels

The ANDR-1 wildcat well, which later led to the discovery of the giant Ghawar field, is currently both the longest production run-life and the highest cumulative production well in Saudi Arabia. The story of this historic well begins when drilling resumed across the Kingdom following a pause during the second World War.

‘Ain Dar was the most obvious location to restart wildcat drilling due to its close proximity to existing producing facilities at Abqaiq, one of our oldest oilfields which was discovered in 1940.

Drilling of ‘Ain Dar began in 1948, with production starting in 1951 at an extraordinary rate of 15,600 barrels per day (bpd) of ‘dry oil’— which contains only a small amount of basic sediments.

Although conventional wells are known to start producing a higher volume of water a number of years into commercial production, the dry oil at the ‘Ain Dar well continued to flow for a staggering 49 years, before it first produced the first water volumes in 1999.

Today, despite it being one of our earliest wildcat wells, it continues to deliver 2,800 bpd — some 73 years after production first started at the site — which is possible thanks to the continuous adoption of new, improved extraction technologies. Remarkably, the original well casings are still in place, showcasing the workmanship and quality of materials used by our engineers in the 1940s.

SFNY-1 (Safaniyah)

Start of production: 1957

Cumulative production: 33 million stock tank barrels

In 1939, geophysicist Dick Kerr drew a speculative red arrow on a map of Northeast Saudi Arabia and alongside it he wrote, “possible high area offshore,” indicating that there was a chance of finding oil in that region. The arrow pointed out into the Arabian Gulf, past a spit of sand called Safaniyah. Kerr's cryptic remark was actually an informed prediction about the strata that underlay the Gulf, which aimed at implying to fellow Aramco geologists that an oil-bearing structure might be found off Safaniyah. Kerr was right. The "high area" was indeed there, as was the oil reservoir, below thousands of feet of water and earth.

They pushed ahead with the exploration of the vast concession area, but within three years World War II had curtailed all exploration and development. When the world-wide search for new oil sources shifted back into high gear after the war, in 1951 our early engineers began work at wildcat well SFNY-1, making it the first well drilled by Aramco in the Arabian Gulf. The location of the well — which is about 3.3 km offshore — was chosen, in part, due to the interpretation of marine seismic data.

It took three months to complete the drilling required to access the well. The initial testing confirmed that there was oil in the region, with Safaniyah later proven to be the largest offshore oil field in the world.

Today, SFNY-1 acts as an observatory well, meaning it helps the Company monitor and gather data on reservoir conditions over time. This information helps enhance production strategies, manage reservoir performance, and ensure the efficient long-term extraction of hydrocarbons.

KRSN-1 (Khursaniyah)

Cumulative production: 103 million stock tank barrels

The story of KRSN-1 began when Aramco’s geologists spotted an apparent structural high at Jebel Faidha, a prominent hill in the area. They used structural drilling — a drilling technique used to drill shallow holes to examine the geological structure beneath the earth's surface — which revealed layered rock in the form of an elongated dome. This sparked hope that there was indeed oil in the region, and the top of the dome was staked as a wildcat location.

Over its six-decade life, this well has been an enduring symbol of success as, remarkably, KRSN-1 has never been sidetracked — meaning that no secondary wellbore has had to be drilled away from the original one.

To help ensure that the well preserves its integrity and high-producing status, we carry out industry best practices in terms of continual surveillance and maintenance.

KRSN-1 is still flourishing, a landmark of reliable asset management with one of the highest cumulative production in all Northern Area onshore fields.

ZULF-1 (Zuluf)

Start of production: 1973

Cumulative production: 77 million stock tank barrels

ZULF-1 is another prominent wildcat offshore well which still produces oil today. The well was unveiled in 1965, and drilling work took about a month including well logging, (the practice of making a detailed record, well log, of the geological formations while drilling) and drill-stem testing (a procedure for isolating and testing the pressure, permeability, and productive capacity of a geological formation).

Production from ZULF-1, however, did not actually start until 1973, due to the challenge of mobilizing offshore infrastructure with the limited resources available at the time. Because the well was nearly 40 miles northeast of the shore facilities serving the offshore Safaniyah field, ZULF-1 entire gas-oil separation process was temporarily set-up offshore. Crude oil from ZULF-1 flowed into a floating plant above the sea, where the associated gas was then removed, before being sent on through underwater lines to a floating storage tank anchored in the Gulf. After it was loaded, the oil was pumped to other seagoing tankers safely moored just a mile away. This process continued for three years until permanent offshore and onshore gas-oil separation plants were built in 1977.

Despite the challenges, ZULF-1has logged a cumulative production of 77 million stock tank barrels since 1973.

More from Elements

The material in this article is intended to be for general informational purposes only, and readers should not place undue reliance on the statements or opinions therein. Any information provided speaks only as of the date this content was published and Saudi Aramco undertakes no obligation to correct, update, or revise any statements or opinions made in or implied by this article.