There are many reasons why the Manifa oil field project is extraordinary. And perhaps more than any of our other mega projects, it demonstrates what can be achieved when we apply creativity, determination, and our engineering prowess to delivering solutions to the seemingly impossible.

Overcoming the impossible

The journey began back in 1957, when the Manifa oil field was discovered — a huge six-reservoir field stretching 45km long and 18km wide, lying in less than 15 meters of water.

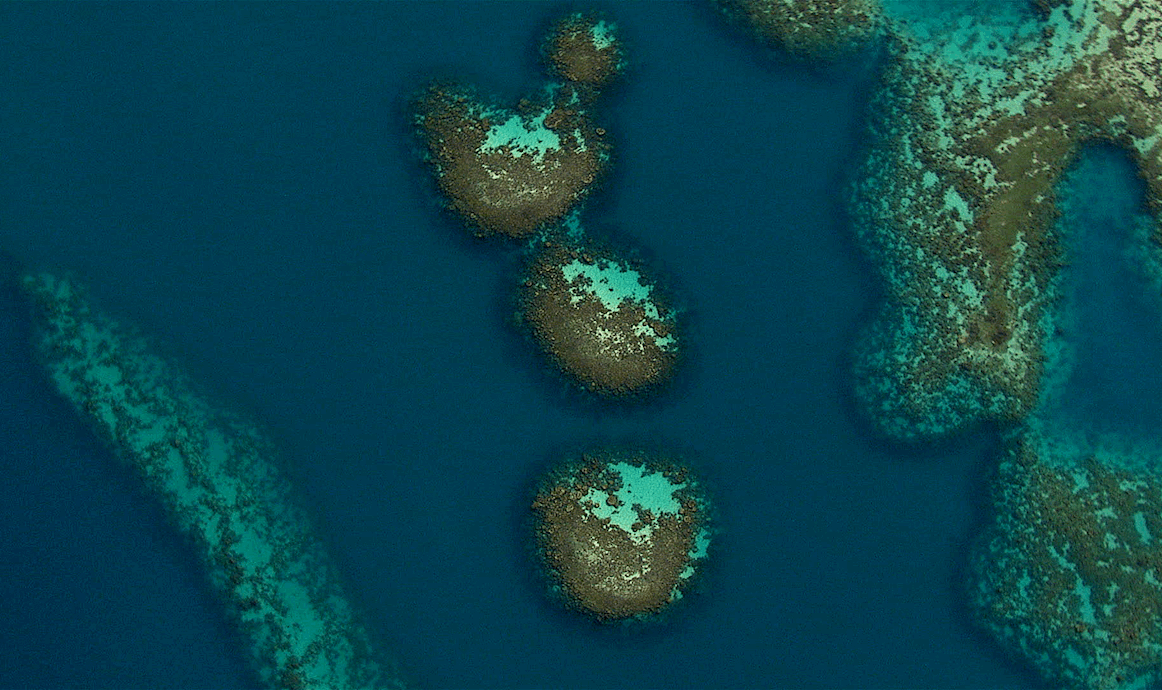

However, it’s not just a treasure trove of oil and gas hiding beneath the bay, but also a delicate habitat of seagrass and coral reefs. The turquoise waters are teeming with marine life, from pearl oysters to sea snakes, shrimps, crabs, dolphins and sea turtles, including the endangered Hawksbill turtle. It’s also a safe haven for migratory birds.

As the oil lay just beneath the shallow waters, it presented a major environmental challenge. Conventional Shallow water drill rigs could damage the fragile marine environment. A risk we weren’t willing to take.

The turquiose waters of Manifa are a haven for migratory birds

"The challenge was to reach the oil without destroying the environment, so the team had to think outside the box, and come up with a radical solution."

Faisal Nughaimish, Drilling General Supervisor

Manifa Bay plays an essential role for humans too. It acts as the lifeblood not only for fishermen and their communities. With an ecosystem sensitive to overfishing and pollution, preserving this underwater ‘museum’ was critical to our corporate and community objectives.

So in 2006, with an initial investment of $10 billion, the adventure to find the best way to produce oil from a shallow, ecologically-delicate, offshore oil field sprang into action.

Rising to the challenge

We began with an intensive planning phase.

We’d need a revolutionary new approach. We’d need engineers, environmental protection officials, scientists, geologists, and marine specialists.

We’d need to deploy innovative drilling techniques in the shallow waters. We’d need technology that didn’t exist yet. We’d need extensive engineering and ecological assessments, to make sure the marine ecosystem wouldn’t be affected.

Finally, we’d need to learn from other similar projects, to avoid any potential pitfalls in construction.

The number of obstacles were daunting. But our engineering heritage had already enabled us to complete many extreme engineering projects, transforming our company into the world’s unprecedented production powerhouse. Here’s how we did it at Manifa Bay.

Giant-sized engineering

To avoid damaging the fragile ecosystem, our engineers needed to devise a radical new approach. They shunned the easy option of building 30 offshore platforms, and came up with the idea to convert over 70% of the field into an onshore field.

This ground-breaking design meant creating 27 man-made islands, each one the size of 10 soccer pitches, all made from 45 million cubic meters of sand reclaimed from the seabed.

The islands would act as onshore drill sites above the offshore oil field, and would be linked by a 41km causeway. Being a company of engineers as well as oil experts was key to the project.

Perfecting our ideas

Originally the plan was to build the causeway from coast to coast across the bay. However, before beginning construction we commissioned extensive research into this sensitive and important marine environment, in partnership with the King Fahd University of Petroleum and Minerals (KFUPM).

It showed the need to maintain water circulation and allow marine life to move freely from deep to shallow water. We therefore factored in an opening between causeway and coastline, and 13 bridges up to 2.4km in length were added, to keep the ocean currents circulating naturally and dispersing vital nutrients and oxygen throughout the bay.

13 bridges, up to 2.4km in length, help keeping the ocean currents circulating naturally.

The research also allowed us to carefully position the man-made islands and causeway, to preserve the coral reefs, avoid interfering with the migration paths of various marine species, and make sure the bay remained a perfect environment for shrimp and fish populations to grow.

Our designers and engineers spent 4 million hours on the design phase alone, with 136,149 engineering drawings and plans to perfect the 27 islands, 13 bridges, 13 offshore platforms, 15 onshore drill sites, 350 new wells, injection facilities, multiple pipelines, and a 420-megawatt heat and electricity plant.

Bringing new technology to life

Below ground, the challenges were no less demanding. As the six enormous reservoirs of up to 40 km long are stacked one on top of the other, we had to invent new technology from scratch. And so we built the nuclear magnetic resonance tool especially for Manifa, to create real time 3D profiles of the reservoir layers.

This allowed geologists to accurately tap into reserves at extreme distances, through a heavy layer of tar, from wells on the surface.

“We set so many challenging goals, important caveats, and benchmarks. There was a lot of innovation. We looked at ways and means to challenge ourselves, and the program was accomplished under budget.”

Mohammed Abdulkarim Manager, Manifa Project Department

Protecting the heroes

With so many thousands of workers bringing our engineering dream to life, their safety was our greatest concern. We identified hydrogen sulphide gas (H2S) hotspots that needed specialized study and risk management.

As a result, a control room was installed to monitor wind speed and a digital map identified potential H2S zones. All contractors were required to meet stringent safety standards, and more than 40,000 workers were trained in H2S awareness.

In recognition, our program for health and safety was awarded the International Corporate Health and Productivity Prize by the Institute for Health and Productivity Management in 2013.

The health and safety of our people is paramount.

Powering ahead

In 2013, oil production began three months ahead of schedule and more than US$ 1 billion under budget. With our ingrained commitment to quality, we carried out more than 5,000 visits to vendors and manufacturers to check the quality of the project’s materials.

By July 2013, the project’s first milestone to produce 500,000 barrels of oil per day was achieved, and by 2017 the ultimate target of 900,000 per day was reached.

To process this amount of oil, we developed the Manifa Central Processing Facility, which has three identical gas-oil separation plants (GOSPs), each designed to treat 300,000 barrels per day for delivery to other refineries in the Kingdom: 1) SATORP, a world class refinery marking a partnership between Aramco and TOTAL; 2) YASREF, a joint venture between Aramco and China Petrochemical Corporation (Sinopec); and 3) Jazan Refinery, wholly owned and operated by Aramco. And over 9,000 km of pipes and cables were used, both above and below water, to deliver the oil to our customers.

The project received the “Innovative Oil Project of the Year” award by using best-in-class technologies in infrastructure, drilling and production activities, and because it involved more than 80 million hours without injury — one of the best safety records in the industry.

Planning the mega-project

In 2006 we began an extensive planning phase to develop the Manifa oil field in the most economical and environmentally-friendly way.

Manifa in numbers

The environmental challenge

“The concept of how to develop an offshore shallow water field and take care of the fisheries and the sensitivity of the ecosystem, was quite unique for many of us as engineers.”

Nabilah Al-Tunisi, General Manager

Visitors to Manifa Bay today find themselves surrounded by the beauty and magnificence of an island-city floating within the Arabian Gulf, where old and new come together — environmental serenity amid a gleaming oil-producing infrastructure.

The project’s innovative engineering approach, designed to nurture the environment, generated interest far and wide, with National Geographic coming to create a film about its work and impact.

Celebrating victory

To protect the highly sensitive ecosystem in Manifa, we followed strict environmental policies enforcing drilling, land, and air protection measures, working once again with the King Fahd University of Petroleum and Minerals.

“The 10 year partnership with the Saudi Aramco Environmental Protection Department and King Fahd University of Petroleum and Minerals was initially established to protect the ecosystem, through developing a creative causeway design and conducting a survey of the marine environment at Manifa Bay, before and after the causeway construction. However, we didn’t stop there. Instead, we capitalized on this partnership, to improve and increase the density of marine life.”

Mohammed Al-Ghamdi, Manager of the Manifa Producting Department

Scientists from KFUPM closely monitored the delicate ecosystem in the bay, filming the coral reef and taking water samples on a weekly basis to check there was no change in the environment. And the monitoring continued well after the project ended.

The results of this careful collaboration are already paying off. Far from destroying the fragile ecosystem in Manifa Bay, the scientists have proven how the causeway design has not only maintained but even enhanced the natural circulation of tidal waters in and out of Manifa Bay.

Increased oxygen actually means a healthier environment for shrimp and fish populations. Seagrass meadows have increased by 70%. Coral reefs have grown in size and are spreading onto the rocks of the causeway itself.

The Manifa Project has been awarded for excellence in environmental technology.

Going the extra mile

We also wanted to make sure the coastal reserve in Manifa was developed in a way that enhances the natural biodiversity of the whole region. To revitalize the mangrove regions along the Arabian Gulf coast, we planted 250,000 trees in 2013 alone, as they offer a refuge for migrating birds and a nesting ground for ospreys and flamingos. We even built three nesting platforms to provide a safe haven for them. These habitats are among the most productive ecosystems in the marine environment, forming the nursing grounds for commercial fish, shrimp, and crabs — essential to the Kingdom’s fishing industry.

Manifa Bay has had such success that Arabian Seas gave us first prize for technical excellence in environmental technology, and we earned a UNESCO environmental responsibility award nomination.

This content is blocked

You need to give permission.

How Saudi Aramco managed to develop a massive offshore oil field in a shallow water site, without negatively impacting the fragile marine environment.

A world of benefits

A world of benefits at Saudi Aramco, it’s not just about our commercial obligations. For the last 80 years we’ve been dedicated to helping communities prosper and flourish.

We want to provide people with the tools they need to accelerate and reach their full potential, so they can help their communities make positive strides in future.

The Manifa Bay project was designed with this in mind, showing our commitment to people, the environment, and the economy, both in the Kingdom and the rest of the world.

New careers, new futures

During the execution phase alone, more than 21,000 jobs were created for people from 25 nations, impacting thousands of families, both directly and indirectly across the Kingdom and beyond.

80% of the workforce were new hires, and 360 young Saudis began their careers as engineers, operators, and maintenance personnel, working under the supervision of experienced Saudi Aramco employees. In 2013, 5.2 million hours of training were completed by Saudi Aramco staff, and 216 employees took part in the Working Woman Program.

As a result, we’re proud that Manifa Bay had tremendous national and global impact, bringing such a wide range of career opportunities to thousands of people across Saudi Aramco.

Fueling the economy

This pioneering project had a significant impact on the Saudi economy, over and above those directly employed by Saudi Aramco.

Areas well beyond Manifa prospered, with a rise in employment, private sector business, and national economic growth. For example, 37% of the all the items bought for the project were manufactured in the Kingdom. Local infrastructure and services have also improved for residents in these areas.

But it wasn’t just the Kingdom that flourished. For example, the design phase used experts not just in Saudi Arabia, but also in Italy, Spain, the UK, Japan, and the UAE.

We awarded 30 prime contracts to national and international companies for the project’s construction, so engineering, procurement, and fabrication activities occurred around the clock in several locations across the globe, fuelling more of the world’s economy.

Committed to energy efficiency

Finally, the Manifa Bay project is the first of its kind for the company, in which co-generation of electricity not only allows us to operate self-sufficiently but also to provide a power surplus. Moreover, oil production at Manifa provides the energy equivalent to meeting the needs of 100 million people around the world.

Recognized for success

Manifa Bay has been called a wonder of the modern world, achieved by collaboration from exceptional teams around the globe. Its success has been widely recognized and we’re proud to have received a number of high-profile awards.

- Arabian Seas awarded Saudi Aramco first prize for technical excellence in environmental technology.

- The project received the “Innovative Oil Project of the Year” award by using best-in-class technologies in infrastructure, drilling and production activities, and because it involved more than 80 million hours without injury — one of the best safety records in the industry.

- Manifa engineering design for oil production and environmental care was nominated for a UNESCO Environmental Responsibility Award.

- The Saudi Aramco program for health and safety was awarded the International Corporate Health and Productivity Prize by the Institute for Health and Productivity Management in 2013.

Sustainability

Sustainable practices are essential to ensuring that Aramco continues to thrive throughout the global energy transition.