How Aramco’s circular economy thinking can help the planet

Circular economies manage resources more sustainably.

- Traditional linear economies waste resources but circular economies keep reusing and recycling materials

- Circular economies start with design to lower their carbon footprint

- In 2020 Aramco set itself a path to become a leading circular economy company

One key route to a sustainable future is conceptually very simple: the circular economy. It is an approach that is gaining ground around the world.

Aramco is taking steps — both practical and cultural — to embed circularity into the Company. This involves re-examining business processes from top to bottom and training people in a new way of thinking.

A Circular Economy Taskforce was set up in 2020. After reviewing best practice from around the world, it created seven key principles that can guide adoption of circular economy thinking in Aramco. A pilot project across eight departments came up with more than 200 circular economy examples and initiatives. Now a broader roll out is taking place across the Company and the principles have been introduced into capital project guidelines and engineering standards.

The benefits of this circular economy approach are already beginning to show and are receiving recognition: Aramco is the European Foundation for Quality Management’s Circular Economy Challenge Winner for 2021.

What is the circular economy?

The circular economy seeks to move us away from the linear “take, make, and dispose” system that’s been practiced from the start of the Industrial Revolution in the 18th Century. Now the aim is to design systems and business models in order to retain the maximum value of resources through the efficient management of materials and products, in particular by reducing waste and maximizing reusing, remanufacturing, and recycling of materials.

Effective management of resources is vital to reach the ambitious targets set by some G20 countries.

Seven principles for circularity

Acting in a circular economy way forces a total rethink of how business is done. “This model really changes the status quo,” says Yaser Shafie, lead of the company’s Circular Economy Taskforce. “As well as aiming to achieve effective and sustainable performance, there are a lot of economic benefits to be gained.”

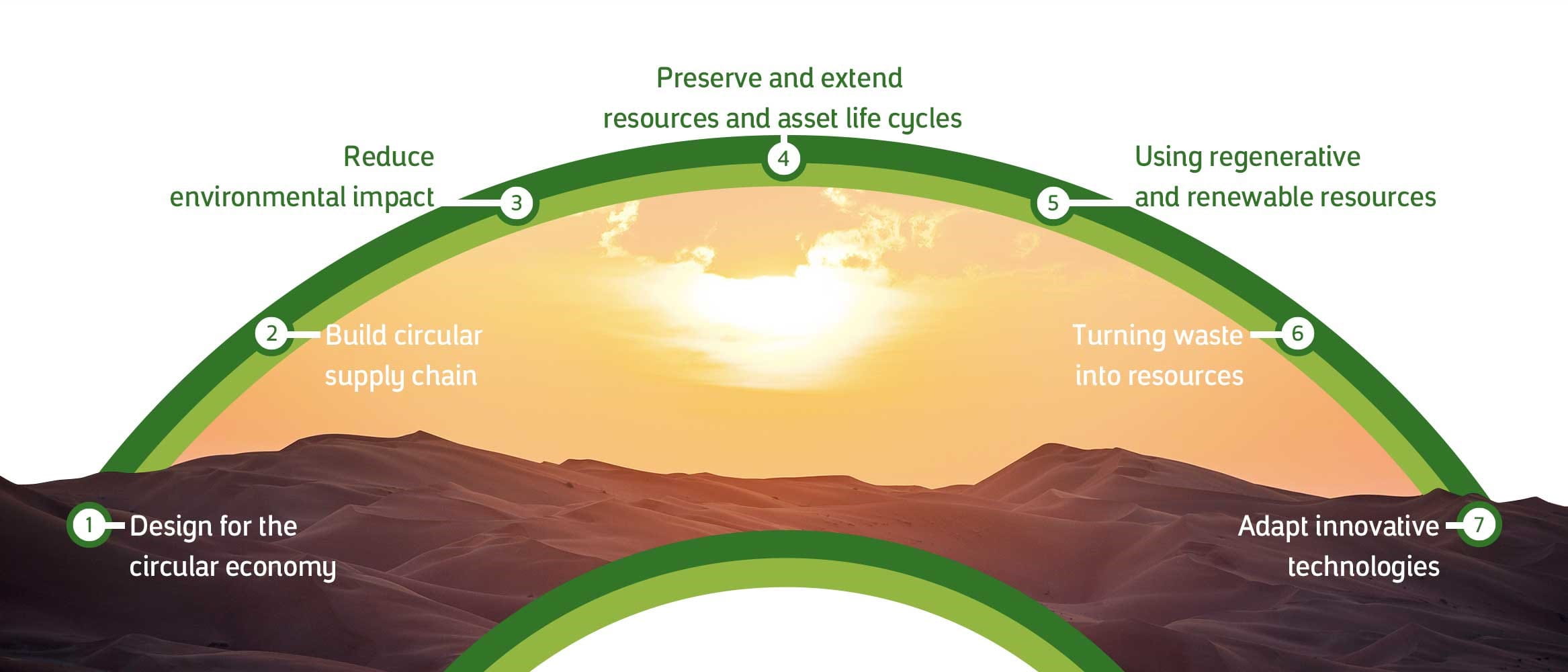

The taskforce has developed seven key principles that are being applied across the company’s operations:

Our seven point strategy for circularity

• 1 Design for the circular economy — this means designing sustainable and effective processes, systems, assets and facilities.

Standardization and modularization are key circular design concepts that Aramco already implements. One example is the Midyan gas plant, which uses modular, skid-mounted structures rather than the usual stick-built approach, reducing construction material usage and creating significant cost savings.

• 2 Build circular supply chain — utilizing circular supply chains and reverse logistics contributes to closing material loops and minimizing waste creation.

In 2020 alone, our scrap-to-commodity program successfully recycled 220,000 drum containers and 84,000 tons of steel. Reintroducing these materials to local manufacturers as feedstocks eases the pressure on raw materials extraction and allowed us to recover over $30 million of value.

• 3 Reduce environmental impact — we focus on decarbonization to reduce greenhouse gas emissions, as well as the conservation of precious water resources.

Our carbon capture project in Hawiyah NGL Recovery Plant minimizes CO2 emissions into the atmosphere and has so far prevented the emission of 3 million tons of CO2. This fits with the circular carbon economy approach that was endorsed by the G20 in 2020 to reduce, reuse, recycle and remove CO2 emissions. This CO2 can then be treated as a resource in itself, in processes such as enhanced oil recovery and concrete curing.

• 4 preserve and extend resources and asset life cycles — our lifecycle management programs seek to ensure full utilization of our equipment, improving their longevity by capturing opportunities to reuse, repair, upgrade, and redeploy assets.

One example is the recent upgrading and redeployment of 21 gas turbines instead of replacing them. This prevents demand for new raw materials to build and transport new equipment, as well as avoiding unnecessary capital expenditures.

• 5 Using regenerative and renewable resources — the idea is to maximize the deployment of renewable, regenerative and non-toxic resources, and to take less from the planet.

Our Midra business center uses solar energy through PV cells installed on the panels that shade the car parking area. This generates enough energy to completely power the building.

• 6 Turning waste into resources — there is more we can do with materials that are currently disposed of.

Among other examples, we take treated waste water from the company’s residential communities in Dhahran that has been rejected from drinking-water plants and reuse it for irrigation and to cool centralized air-conditioning plants, conserving billions of gallons per year of groundwater.

• 7 Adapt innovative technologies — we have built a state-of-the-art Fourth Industrial Revolution Center that serves as a hub for digital solutions, with a focus on process optimization, asset reliability, and operations efficiency — all of which are key aspects of our circular economy implementation.

These include energy intensity monitoring to analyze energy performance across all Aramco facilities. As of 2020, energy intensity initiatives have saved a cumulative total of 238 million barrels per day oil equivalent, as well as CO2 reduction of 27 million tons.

Building on existing DNA

Many of the principles of the circular economy have long been part of Aramco’s operational DNA. Back in the 1970s, for example, instead of flaring gas from its oil wells, Aramco built its massive Master Gas System to capture and utilize it.

Energy efficiency and optimization is a guiding principle for our engineering teams.

In 2020, in a move championed by chief engineer Dr. Jamil J. Al-Bagawi, a roll-out plan was created to institutionalize the circular economy across the Company and further embed it in the company’s future.

“We need to ‘close the loop,’” said Aramco President & CEO Amin Nasser, calling for circular systems for carbon and other materials, “to the maximum extent possible.”

More from Elements

The material in this article is intended to be for general informational purposes only, and readers should not place undue reliance on the statements or opinions therein. Any information provided speaks only as of the date this content was published and Saudi Aramco undertakes no obligation to correct, update, or revise any statements or opinions made in or implied by this article.