POWERED BY HOW

Developing efficiency solutions to help meet the world’s growing demand for energy

Aramco is an energy and chemicals company with oil and gas production as its primary business.

At Aramco, technology is viewed as a critical enabler of efficiency and reliability, as well as helping to reduce greenhouse gas (GHG) emissions and achieve our ambition toward net-zero Scope 1 and Scope 2 GHG emissions across our wholly-owned operated assets by 2050. That’s why we actively invest in cutting-edge solutions to optimize Upstream operations, from energy exploration to production stages.

These innovations, combined with the expansive scale of our operations, enable us to consistently deliver energy while demonstrating our aspiration to support global climate ambitions.

We’re optimizing operations through cutting-edge technology …

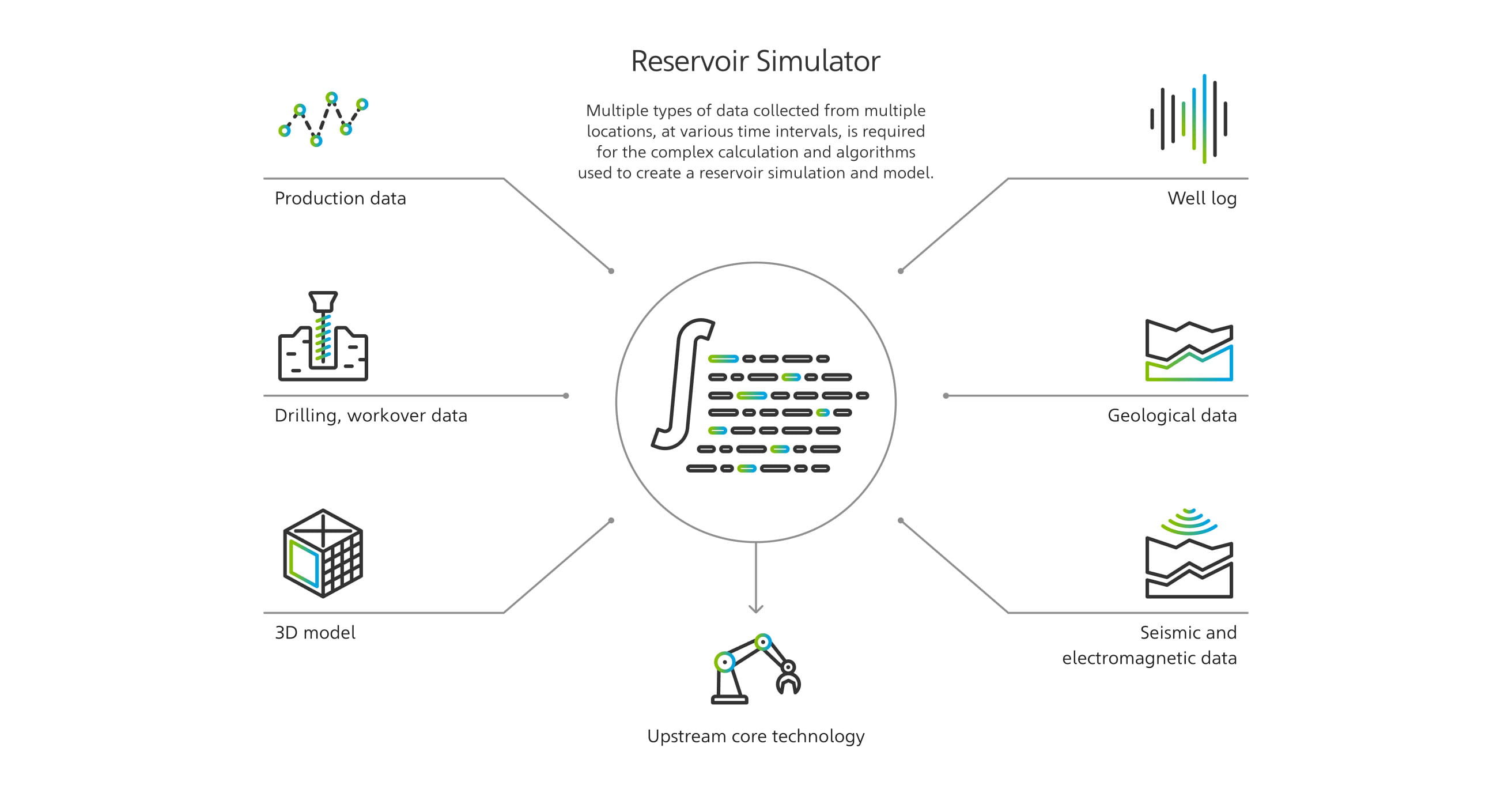

Aramco Upstream operations are supported by sophisticated technology, from our GigaPOWERS reservoir simulator to machine learning, advanced analytics, and AI-powered solutions. We also have a dedicated digital team to innovate as needed. These capabilities enable us to safely extract energy, assess reservoirs, and complete Upstream production activities.

… to ensure we deliver energy reliably and efficiently where it’s needed

Reliability with responsibility

Our in-house technologies span Upstream disciplines from geology and geophysics to drilling, reservoir engineering, and production engineering. A hallmark of our innovations is that they aim to help reduce our GHG emissions.

As our 2022 Sustainability Report shows, 59% of our total R&D spend in 2021-22 supported sustainability-related projects. Further, in 2024, we allocated a further $4 billion to our global venture capital arm, Aramco Ventures, bringing the total to $7.5 billion. A substantial part of this investment is expected to target nurturing innovative start-ups that have the potential to support our ambition to achieve net-zero Scope 1 and Scope 2 GHG emissions across our wholly-owned and operated assets by 2050.

Key facts

$7.5 billion

total venture capital allocation (2024)

59%

total R&D spend on sustainability ($435 M in 2021-22)

-15%

reduction in upstream carbon intensity by 2035

~52 MMtCO2e

reduction in emissions by 2035

Technology that delivers

Leading innovation

Technological innovation contributes in helping maintain an efficient, reliable, and responsible global energy supply. The rapid pace of our innovation means that, at any given time, new technologies are in development, with some of those mentioned below yet to become available at scale.

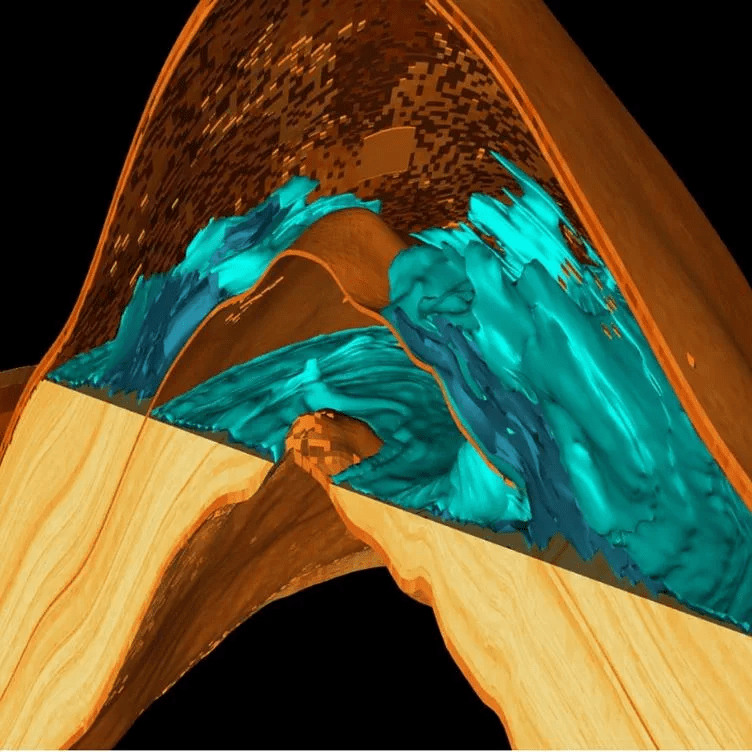

Due to the scale of our operations, we pioneer many new technologies in-house. For example, we created our original GigaPOWERS reservoir simulator because no existing solution could meet our specifications.

The latest instance of GigaPOWERS (GP V9), launched in 2023, takes just eight hours to run a 2 billion-cell model that details 300 million tons of stored carbon dioxide (CO2) in a saline aquifer. This processing power helps us manage reservoirs optimally with the aim of staying on track with our 2035 carbon-intensity targets.

Evolving technology expertise

This content is blocked

You need to give permission.

Our innovations combine the power of AI, Big Data, and the Industrial Internet of Things to help drive safety, efficiency, and reliability at every operational stage. For example:

- Our new, robotic Autonomous Seismic Acquisition Device enables us to access and survey out-of-reach areas efficiently, while keeping technicians safe.

- At the extraction stage, our advanced Drilling at the Edge platform brings together people, sensors, and computing power on a rig. Using real-time data, expert teams can streamline operations with faster, more informed, and safer decisions.

- In the field of subsurface applications, our industry-first perforating tool, our High-Power Laser, creates a unique perforation network design without damaging the formation, making the technology safer while potentially reducing environmental impact.

- Responsible water management is a key environmental focus. Our pioneering Zero-Liquid Discharge solution removes contaminants and salts from oil and gas field-generated water, cutting liquid-waste discharge. We can also reuse treated water to inject into the reservoir fracking operations to promote circular water economy and hydrogen production.

These and other subsurface innovations were developed through EXPEC ARC. They help drive our innovation leadership while keeping us at the forefront of responsible energy management.

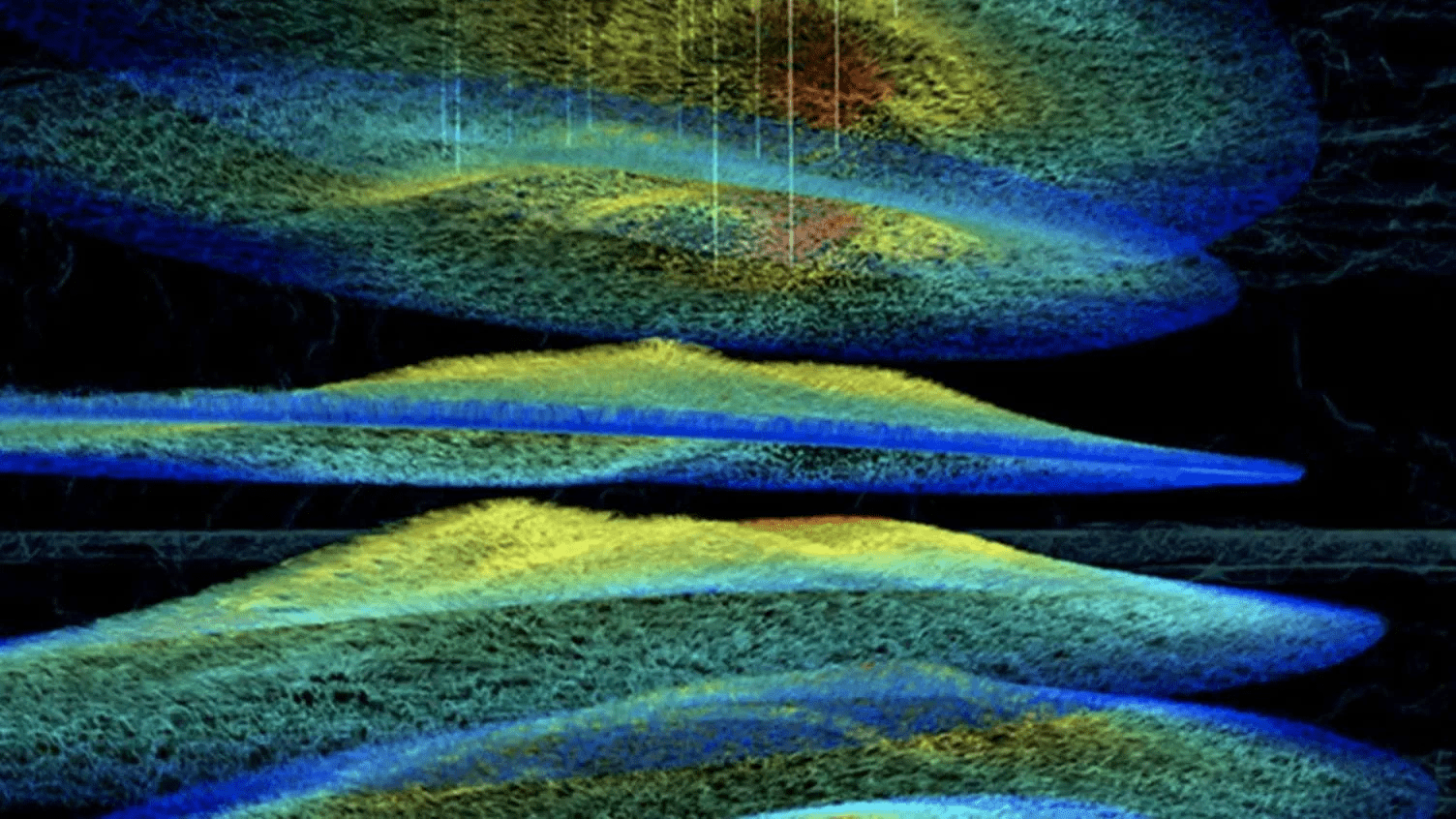

Advanced reservoir modeling

These sensors, along with numerous other data-acquisition methods, enable us to build high-resolution pictures of not only how a reservoir was formed, and what is happening in it today, but also how the conditions may change in the decades to come.

Detailed analysis — including scrutiny of geological, 3D, seismic, geochemical, fluid, drilling, and production data — helps us more effectively place wells, manage long-term production, and discover new deposits.

We also implement digital oilfields, using predictive analytics to anticipate adverse events before they arise in the real world. This approach helps us enhance operational safety and efficiency, and minimize disruption. Empowering us to make informed, efficient, and cost-effective decisions throughout the exploration, extraction, and production lifecycle.

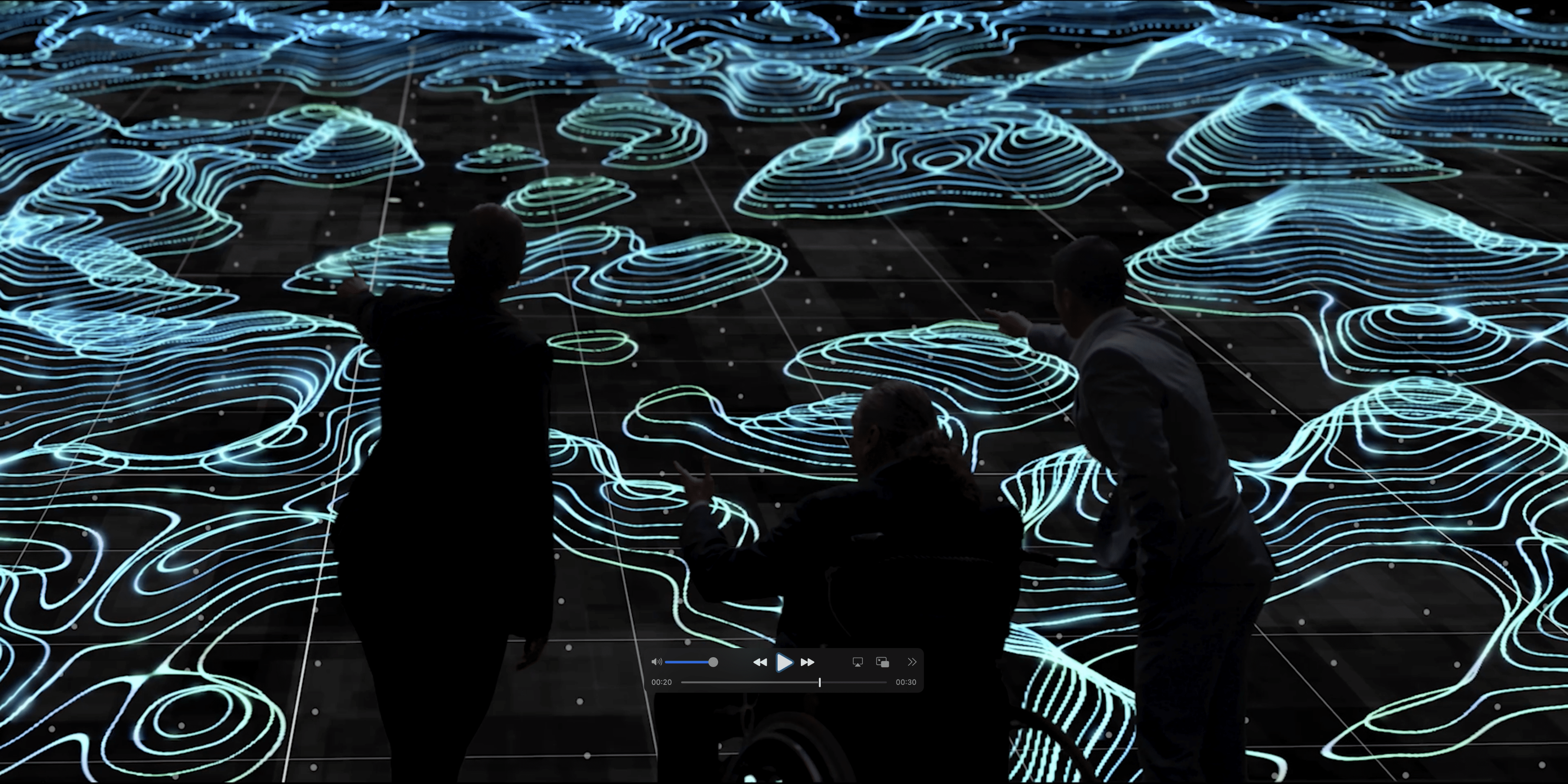

Upstream Metaverse

Our new Upstream Metaverse digital platform, developed in-house, brings together operational data, teams and collaboration hubs into a single, immersive environment.

This experience enables our managers and technical specialists to move together in real-time between different data worlds, inspecting reservoir models, well models, surface facilities, and more. Working from anywhere, teams can carry out deep-dives into the field, slice-and-dice the data model, and easily collate their findings.

The Metaverse hosts key operational meetings, such as field reviews, and enables our technicians to run virtual scenarios and make predictions that inform on-the-spot decision making.

Powering tomorrow, safely

As we continue to strive to meet our targets to reduce greenhouse gas emissions by 2035, we are prioritizing five key levers. These include enhancing energy efficiency in both Upstream and Downstream assets, and developing carbon capture and storage solutions.

Our technology innovations could play an essential role in achieving these aspirations, as we constantly aim to improve our ability to enhance efficiency, save energy, and help support the world’s transition to lower-emissions energy solutions.

Powered by how

Discover how one simple question – how? – powers everything we do.